Part 1 of the Series: “The re-unit Path to Sustainable Optimization”

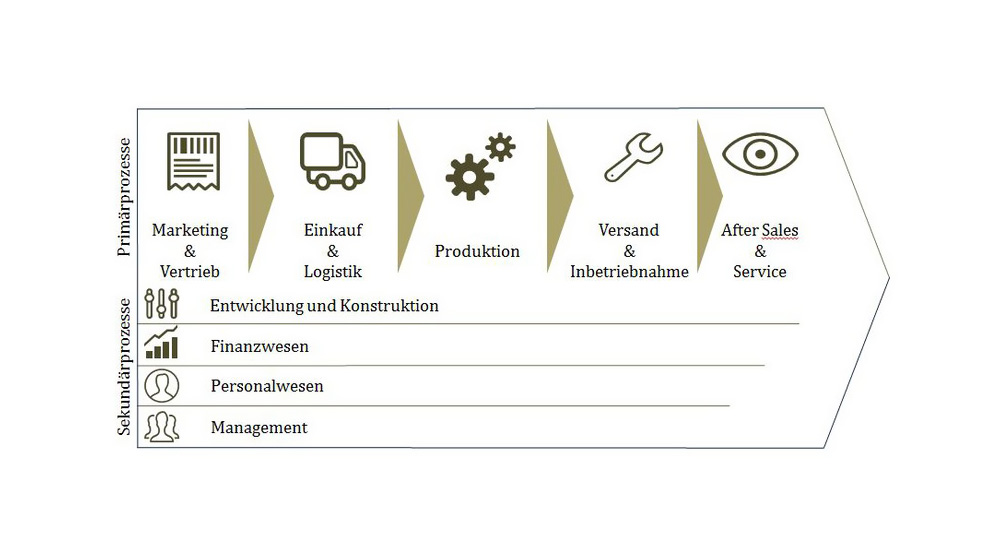

The value stream includes all value-adding and non-value-adding activities necessary for the production of a product or the delivery of a service.

It often represents an underutilized internal source of profit growth. But how should its optimization be approached correctly?

Business Process Reengineering and Lean Methodology

Two approaches are available for process optimization. One is the top-down approach of Business Process Reengineering; the other is the bottom-up approach of Lean methodology, following the principles of the Toyota Production System. Both approaches have advantages and disadvantages depending on the phase of a company.

Business Process Reengineering delivers short-term success. It is often used at the beginning of corporate restructuring to achieve quick wins through strategic, typically non-consensus-driven top-management directives. The downside is that fatigue and employee resistance to the measures set in quickly. The effects are generally of a short-term nature.

Lean methodology, by contrast, aims to introduce employee-driven, lean, and efficient processes into the organization. This approach usually takes longer, but the processes are more robustly implemented and sustainability is better ensured.

The re-unit Path

Based on experience from numerous projects, re-unit recommends a goal-oriented combination and parallel application of both approaches. This allows for early improvements while initiating the sustainable implementation of robust processes.

re-unit begins value stream optimization by defining strategy-oriented objectives and setting the framework. This happens top-down—but already with the involvement of key personnel. This ensures realistic objectives and higher acceptance. During the conceptual phase, the approach shifts situationally to employee-driven activities. With the involvement of key personnel, lean, robust processes are designed and implemented bottom-up. The early involvement of employees secures the viability of measures from the outset and equally ensures a high level of employee motivation and satisfaction. As a result, most of the set goals are usually achieved ahead of schedule.

As a partner to medium-sized companies, re-unit supports the implementation of recommended measures. We are committed to safeguarding the effectiveness of optimization measures through long-term support, including audits of process compliance and continuous improvement processes.

Effects

Through the consistent parallel application of Business Process Reengineering and Lean methodology, re-unit has already achieved significant results together with its clients in the past.

Companies have recorded internally driven and sustainable profit growth through efficient and robust value stream processes—whether in production or administration.

In Part 2 of our series, we will examine “Value Stream Optimization through Lean Methodology in Production.”